ODM (OD-Mounted Electric Pipe Cutting And Beveling Machine)

ODM series electric pipe cutting and beveling machine is a portable cutting and beveling equipment. It has the characteristics of relatively light weight, small radial space, convenient use and simple maintenance. It can be easily and quickly installed on complex series pipelines for cutting and beveling.

This product is widely used in pipeline installation projects and emergency repair operations in petrochemical, natural gas, food, boilers, pharmaceuticals, nuclear power, shipbuilding and other industries.

ODM (OD-Mounted Electric Pipe Cutting And Beveling Machine)

ODM series electric pipe cutting and beveling machine is a portable cutting and beveling equipment. It has the characteristics of relatively light weight, small radial space, convenient use and simple maintenance. It can be easily and quickly installed on complex series pipelines for cutting and beveling.

This product is widely used in pipeline installation projects and emergency repair operations in petrochemical, natural gas, food, boilers, pharmaceuticals, nuclear power, shipbuilding and other industries.

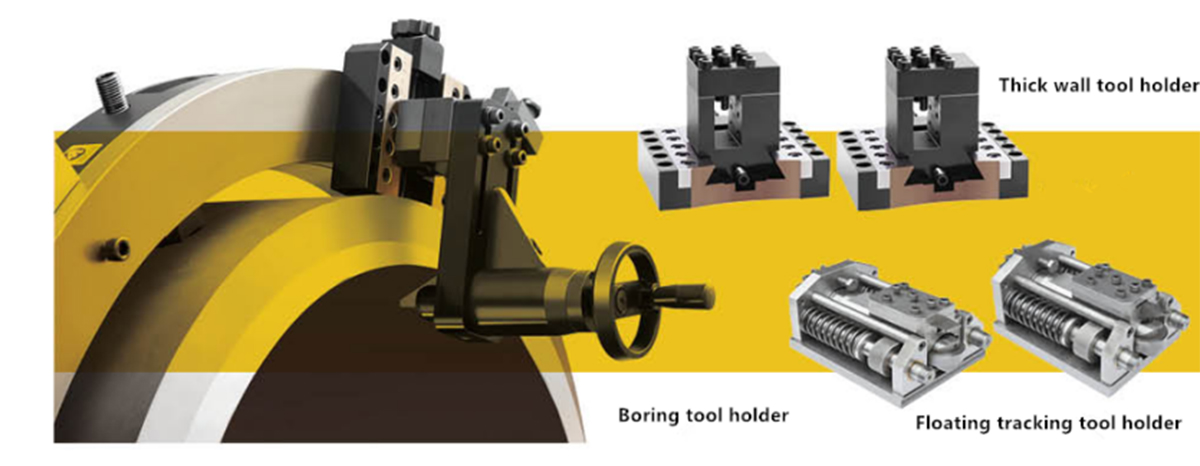

Features:

1. Suitable for processing all kinds of heat-resistant steel and stainless steel large-diameter pipes, and the processing wall thickness can reach 120mm.

2. Online installation, cutting and beveling can be done at one time.

3. Powerful motor can be installed in variable position, suitable for narrow space operation.

4. Completely cold cut, without affecting the material of the pipe, ensuring its wide applicability.

5. Split type design, automatic and manual feed mode, the operation is very simple.

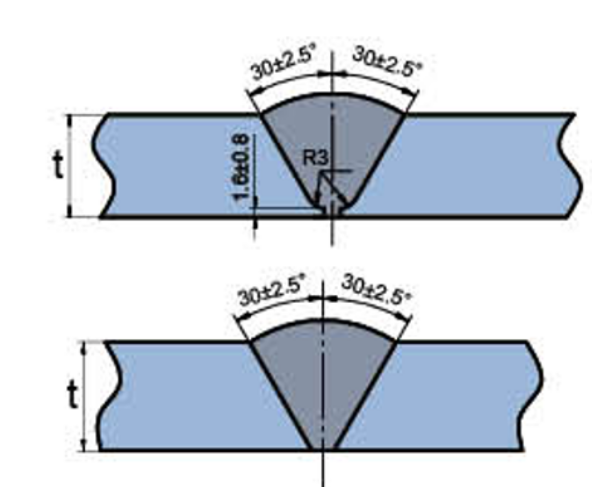

6. It can be processed into different forms of grooves according to customer requirements: single V, double V, and U type.

7. It can be driven by hydraulic pressure (speed regulation), electric or pneumatic.

8. Equipped with Metabo motor, high torque, powerful power, good heat dissipation, motor soft start protection, overload and power failure protection.

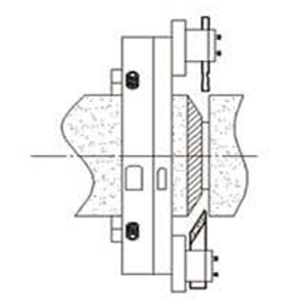

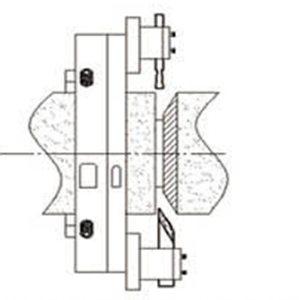

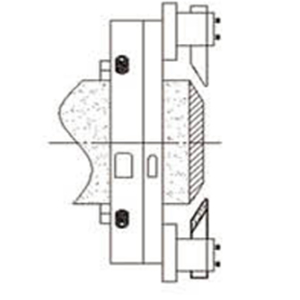

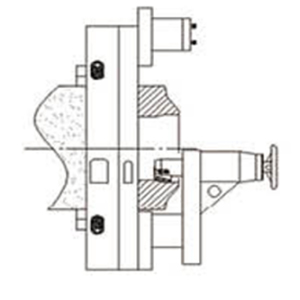

Processing Diagram

Cutting groove processing

Reverse cutting edge processing

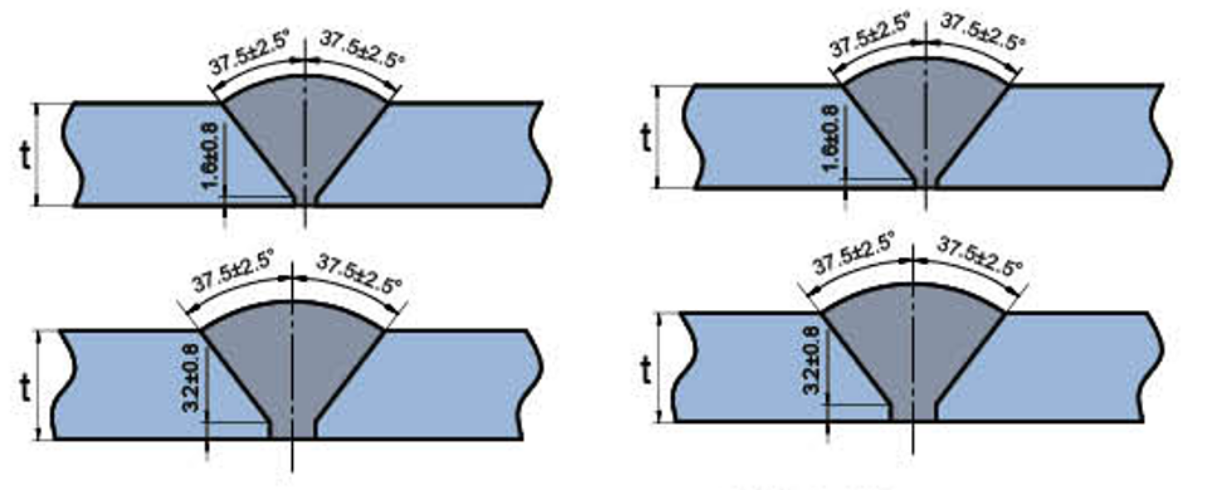

37.5&10 compound groove processing

Double bevel tool bevel processing

Inner slope and boring

Inner slope and boring

Double cutting (cutting) processing

Groove Type

Technical Parameters

| Model | Available Dia. (mm) | Pipe Thickness (mm) | Standard Groove Thickness |

| ODM-89 | Φ25-89 | 3/4"-3" | ≤20 |

| ODM-168 | Φ50-168 | 2"-6" | ≤30 |

| ODM-230 | Φ80-230 | 3"-8" | ≤30 |

| ODM-275 | Φ114-275 | 5"-10" | ≤30 |

| ODM-325 | Φ159-325 | 6"-12" | ≤30 |

| ODM-377 | Φ200-377 | 8"-14" | ≤30 |

| ODM-426 | Φ273-426 | 10"-16" | ≤30 |

| ODM-457 | Φ300-457 | 12"-18" | ≤30 |

| ODM-508 | Φ355-508 | 14"-20" | ≤30 |

| ODM-560 | Φ400-560 | 16"-22" | ≤30 |

| ODM-610 | Φ457-610 | 18"-24" | ≤30 |

| ODM-660 | Φ500-660 | 20"-26" | ≤30 |

| ODM-715 | Φ560-715 | 22"-28" | ≤30 |

| ODM-762 | Φ600-762 | 24"-30" | ≤30 |

| ODM-830 | Φ660-830 | 26"-32" | ≤30 |

| ODM-914 | Φ762-914 | 30"-36" | ≤30 |

| ODM-1066 | Φ914-1066 | 36"-42" | ≤30 |

| ODM-1230 | Φ1066-1230 | 42"-48" | ≤30 |

For wall thickness above 50mm, it is recommended to choose hydraulic drive, please state before ordering, according to the cutting groove requirements, configure a heavy-duty cutting groove tool holder.

Working Site